The quality of lawns mostly comes from the quality of artificial grass fibers, followed by the ingredients used in the lawn manufacturing process and the refinement of manufacturing engineering. Most high-quality lawns are produced using imported grass fibers from abroad, which are safe and healthy. Low grade grass fiber not only has low cost, but also causes significant harm to human health.

Good artificial turf undergoes strict quality inspection, and its safety, quality, and quality are guaranteed to a certain extent. Before manufacturing, they will pass anti-aging and anti-static tests, as well as SGS Class II fire and flame retardant tests, and the safety index meets the international standards. In addition, good artificial lawns undergo quality inspection and testing for harmful and toxic substances, and do not contain harmful substances such as heavy metals. They do not emit a pungent odor under the sunlight. And during the process of drawing and refining, the pulling force of grass fibers needs to be tested. Lawns with strong pulling force and weak pulling force are difficult to recognize in terms of quality.

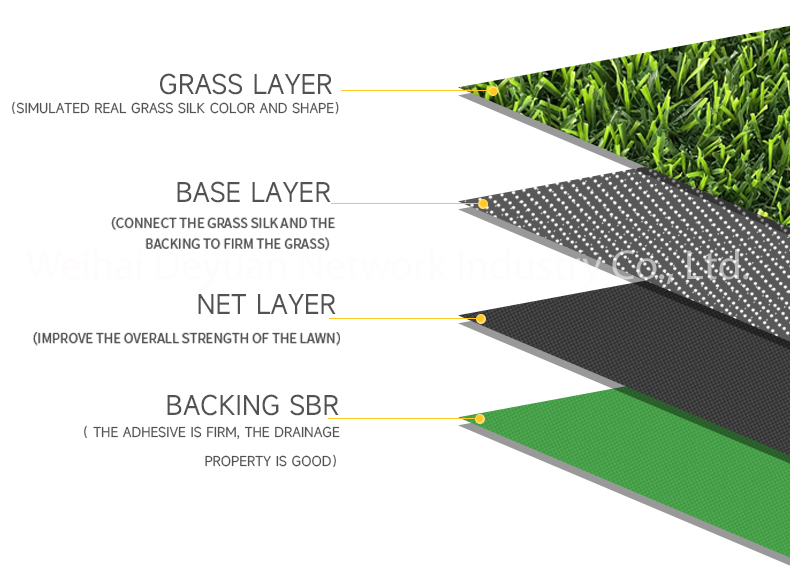

Artificial turf base fabric is also one of the reasons that affects the quality of artificial turf. The artificial turf base fabric is mainly composed of PP fabric, non-woven fabric, and mesh fabric. The quality and thickness of the base fabric must meet certain requirements. There are three types of artificial turf substrates, single layer substrates, mainly PP. Double layer bottom fabric, mainly consisting of PP+non-woven fabric and PP+mesh fabric. The composite base fabric is PP+non-woven fabric+mesh fabric.

PP fabric is what we often refer to as polyester. It has good elasticity, is not afraid of compression, dries quickly, and is easy to clean; Non woven fabric has the characteristics of moisture resistance, breathability, softness, light texture, non flammability, easy decomposition, non-toxic, and non irritating. Mesh fabric has the advantages of high strength, anti entanglement, waterproofing, heat resistance, good breathability, and strong coating adhesion.

Since the artificial turf base cloth is placed at the bottom to directly contact the foundation, and is often exposed to sunlight and rain, or even immersed in water, it must be breathable, waterproof, durable and have good anti-aging effect. If the artificial turf substrate is very thin or the quality of the substrate material is poor, it will rot and crack, seriously affecting the service life of the artificial turf.

On the premise of ensuring quality, PP fabric, non-woven fabric, and mesh fabric each have their own advantages and disadvantages. Considering the durability and service life of artificial turf, it is relatively rare to use single-layer PP or non-woven fabric as the current artificial turf substrate, and most of them use composite substrates to achieve the best usage effect.

Artificial turf adhesive can also affect the quality of artificial turf. The quality of the adhesive determines the tearing force at the bottom of the lawn. The bottom adhesive of the lawn has strong tear resistance, and its lawn quality is also good.

Post time: Dec-04-2023