1. Zaɓin ɗanyen abu da pretreatment

Kayan siliki na ciyawa

Yi amfani da polyethylene (PE), polypropylene (PP) ko nailan (PA), kuma zaɓi kayan bisa ga manufar (kamarfilayen wasannigalibi PE ne, kuma lawns masu jurewa su ne PA).

Ƙara abubuwan da ake buƙata kamar su masterbatch, wakili na anti-ultraviolet (UV), mai riƙe da wuta, da sauransu, kuma a haɗa su sosai ta hanyar mahaɗa mai sauri.

An bushe albarkatun ƙasa don cire danshi (zazzabi 80-100 ℃, lokaci 2-4 hours).

Tushen masana'anta da kayan m

Tushen masana'anta yana amfani da polypropylene (PP) masana'anta mara saƙa ko masana'anta masu haɗaka, wanda dole ne ya sami juriya mai tsage da juriya na lalata.

Adhesive yawanci polyurethane tushen ruwa (PU) ko styrene-butadiene latex (SBR), da kuma wasu high-karshen kayayyakin amfani da muhalli abokantaka zafi narke m.

2. Extrusion da siffanta zaren ciyawa

narkewar extrusion

A gauraye abu ne mai tsanani da kuma narke da dunƙule extruder (zazzabi 160-220 ℃), da tsiri ciyawa yarn ne extruded ta lebur mutu kai.

Ana samar da zaren ciyawa da yawa a lokaci guda ta amfani da shugaban mutuƙar ramuka da yawa, tare da faɗin 0.8-1.2mm da kauri na 0.05-0.15mm.

Mikewa da murzawa

Ana shimfiɗa yarn ciyawa sau 3-5 don haɓaka ƙarfin tsayinsa, sa'an nan kuma an daidaita shi ta hanyar rollers masu zafi ko iska don samar da tsarin igiya / karkace.

Mai raba waya yana raba zaren ciyawa zuwa filaments guda ɗaya kuma yana jujjuya su zuwa igiya don amfani da jiran aiki.

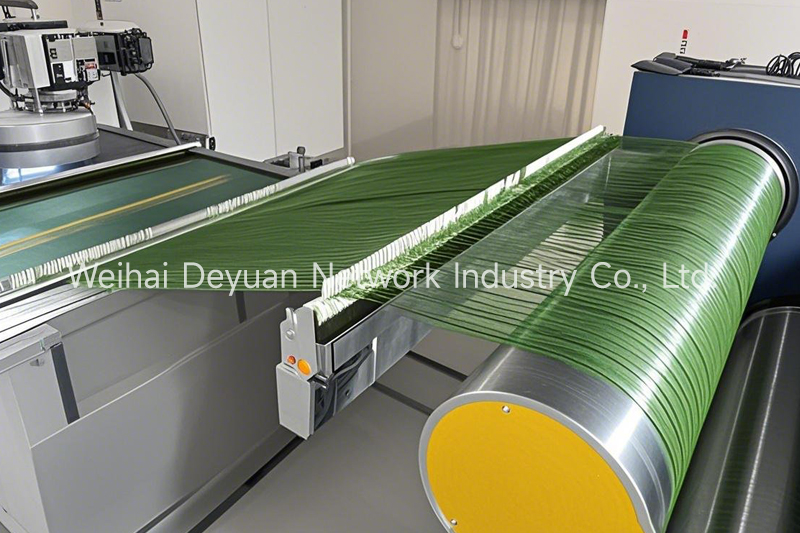

3. Tufting saƙa

Ana saka masana'anta na tushe akan injin

Tushen masana'anta yana buɗewa ta abin nadi na tashin hankali, kuma ana fesa saman tare da wakili mai haɗawa (kamar KH550) don haɓaka mannewar manne.

Tufting inji aiki

Yi amfani da injin tufting gado mai allura biyu, tare da saurin allura na 400-1200 allura/minti da daidaitacce tazarar jeri na 3/8″-5/8″.

An dasa yarn ciyawa a cikin masana'anta na tushe bisa ga ƙimar da aka saita (6500-21000 allura / ㎡), kuma ana iya daidaita tsayin ciyawa daga 10-60mm.

Ainihin saka idanu na matsa lamba na allura (20-50N) don guje wa karyewar allura, kuma tsarin canza yarn yana haɗa yarn ciyawa ta atomatik.

4. M shafi da curing

Rufe na farko

Aiwatar da latex mai kauri 2-3mm styrene-butadiene (ƙarfin abun ciki 45-60%) ta hanyar gogewa ko feshi, kuma ku shiga giɓin masana'anta na tushe.

Infrared pre-bushewa (80-100 ℃) yana kawar da 60% na danshi.

Layer ƙarfafawa na biyu

Haɗin gilashin fiber ragar raga ko polyester raga don haɓaka kwanciyar hankali.

Aiwatar da manne polyurethane (kauri 1.5-2.5mm), kuma yi amfani da tsarin juye juyi sau biyu don tabbatar da ɗaukar hoto iri ɗaya.

Curing da gyare-gyare

Yanke bushewa: matakin farko 50-70 ℃ (20-30min), matakin ƙarshe 110-130 ℃ (15-25min).

Ƙarfin kwasfa na manne Layer dole ne ya zama ≥35N/cm (EN misali).

5. Kammala tsari

Ƙarshen ciyawa

Cikakken mai rarraba ciyawa ta atomatik yana tsefe ciyawa mai ɗaci don tabbatar da daidaiton ƙimar ya fi 92%.

Injin jujjuya wuka na madauwari yana da juriyar juriya na ± 1mm, kuma altimeter laser yana saka idanu a ainihin lokacin.

Magani mai aiki

Maganin antistatic: spraying quaternary ammonium gishiri wakili (ƙimar juriya ≤10^9Ω).

Sanyaya shafi: Ana lulluɓe saman filin wasan motsa jiki tare da cakuda titanium dioxide / zinc oxide, kuma ana rage bambancin zafin jiki da 3-5 ℃.

Ingancin dubawa

Gwajin abrasion (Hanyar Taber, jujjuyawar lalacewa 5000 <5%)

Gwajin rigakafin tsufa (awanni QUV 2000, ƙimar riƙe ƙarfi ≥80%)

Shanye tasiri (nakasar tsaye 4-9mm, daidai da ka'idojin FIFA)

6. Slitting da marufi

Tsagewar tsaye da a kwance

Coiler faɗaɗa iska biyu-axis don juyawa, daidaitaccen faɗin yi 4m.

Tsage wuka madauwari mai sauri (daidaita ± 0.5cm), tsarin sawa ta atomatik yana rikodin bayanan tsari.

Marufi, ajiya da sufuri

PE wrapping film + ruwa kraft takarda hadaddun marufi, ABS m iyakoki an sanya a kan duka biyun iyakar Roll core.

Ana buƙatar kiyaye ajiya daga haske da danshi (danshi ≤ 60%), kuma tsayin daka bai kamata ya wuce yadudduka 5 ba.

7. Tsari na musamman (na zaɓi)

Lawn 3D: tufting na biyudon samar da manyan sassan ciyawa / ƙananan ciyawa, haɗe tare da matsi mai zafi don siffa.

Tsarin ciyawa mai gauraya: tsarin da aka haɗa tare da 10-20% na filaye na ciyawa na halitta.

Lawan mai wayo: Layer fiber ɗin da aka saka, hadedde zafin jiki da aikin jin zafi.

Tsarin gaba ɗaya yana rufe tsarin masana'anta daga albarkatun ƙasa zuwa samfuran da aka gama. Dukkan sigogi an tsara su daidai da ISO 9001 da kumaMatsayin Wasanni Turf Council (STC)., kuma ana iya daidaita tsarin haɗin kai bisa ga takamaiman yanayin aikace-aikacen.

Lokacin aikawa: Fabrairu-12-2025